In the intricate world of electrical systems, where the dance of electrons powers our lives and fuels our technological advancements, a silent guardian plays a pivotal role in ensuring safety and efficiency: the standoff insulator. Ofen overlooked, these unassuming components are essential in maintaining the integrity of electrical structures, acting as a barrier between conductive elements and their surroundings. Understanding standoff insulators is not just about grasping their function; it’s about appreciating their critical contribution to the safety of electrical installations.In this article, we will delve into the fascinating world of standoff insulators, exploring their design, purpose, and impact on electrical safety, illuminating the importance of these unsung heroes in our daily lives.

Table of Contents

- Understanding the Functionality of Standoff Insulators in Power Systems

- Essential Materials and design Features for Optimal Insulator Performance

- Best Practices for Installing and Maintaining Standoff Insulators

- The Role of Standoff Insulators in Enhancing Electrical Safety Standards

- Q&A

- Closing Remarks

Understanding the Functionality of Standoff Insulators in Power Systems

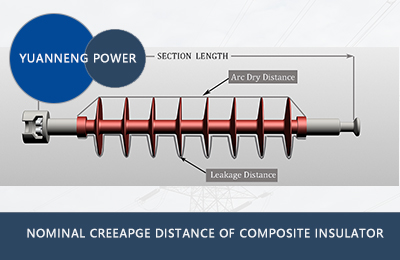

Standoff insulators play a critical role in ensuring the integrity and safety of power systems by providing physical separation between energized components and their supporting structures. These insulators are designed to withstand environmental factors such as moisture, heat, and pollution while maintaining their insulating properties. Common materials used for standoff insulators include porcelain, glass, and various polymer compounds, each selected based on specific performance criteria. The effectiveness of these insulators is measured by their dielectric strength and mechanical stability, ensuring that they can handle not only standard conditions but also extreme weather events without compromising electrical safety.

In addition to their protective role, standoff insulators also facilitate the proper functioning of electrical networks by ensuring adequate clearance between conductors and surrounding conductive surfaces. this clearance is crucial for preventing short circuits and operational failures. Key features of standoff insulators include:

- Versatility: Compatible with various system voltages and configurations.

- Resistance to environmental degradation: Withstand pollution and temperature variations.

- Support structure integrity: Maintain stability under mechanical loads.

To better illustrate their importance, consider the following table that outlines the performance characteristics of commonly used materials in standoff insulators:

| Material | Dielectric Strength (kV/mm) | Typical Applications |

|---|---|---|

| Porcelain | 20-30 | High voltage power lines |

| Glass | 30-40 | Substation equipment |

| Polymer | 15-25 | Distribution systems |

Essential Materials and Design Features for Optimal Insulator Performance

To achieve optimal performance in standoff insulators, the selection of materials is crucial. High-performance insulators are typically made from polymeric composites, ceramics, and glass due to their excellent dielectric properties and mechanical strength. each of these materials offers unique benefits, such as superior resistance to environmental stressors and outstanding insulative capabilities.Polymeric materials are favored for their lightweight, adaptability, and impact resistance, while ceramics provide greater thermal stability and durability under extreme conditions. Glass insulators, conversely, are renowned for their clarity to electric fields, giving them a unique advantage in specific applications.

Beyond material choice, the design features of insulators also play a significant role in their efficacy. Key design elements include surface profile,contamination resistance,and rain shedding capabilities. A smooth surface finish can help in minimizing contamination buildup, which can lead to electrical failure. Additionally, incorporating a hydrophobic coating can improve the insulator's ability to repel water, enhancing its performance during wet conditions. The integration of multi-fingered designs can also provide better resistance against electrical arcing, thus reinforcing overall safety in electrical installations.

Best Practices for Installing and Maintaining Standoff Insulators

When it comes to the installation of standoff insulators, careful planning and execution are paramount to ensure optimal performance and longevity.Before installation, consider assessing the environmental conditions such as temperature and humidity, as they can significantly impact the insulators' functionality. Additionally,ensure you utilize the right tools and safety gear to mitigate any risks during the installation process. Here are some best practices to follow:

- Inspect before installation: Check for any damage or defects in the insulators.

- Follow manufacturer guidelines: Adhere to the specifications provided for spacing and alignment.

- Secure fastenings: Ensure that all bolts and fittings are properly tightened to prevent loosening over time.

After installation, ongoing maintainance is crucial for the reliability of standoff insulators. Regular inspections can help identify potential issues before they escalate into larger problems. Here’s a handy guide to maintaining your insulators:

| Maintenance Activity | Frequency | Purpose |

|---|---|---|

| Visual Inspections | monthly | To check for signs of wear, corrosion, or damage. |

| Cleaning | Quarterly | To remove dirt, debris, and contaminants that can impact performance. |

| Tightening of Fasteners | Biannually | To ensure all components remain securely fastened. |

The Role of Standoff Insulators in Enhancing Electrical Safety Standards

Standoff insulators play a pivotal role in establishing robust electrical systems, acting as a protective barrier between conductive materials and their surroundings. By maintaining a proper distance, these insulators help prevent accidental electrical discharges that could lead to perilous situations.Their ability to support overhead lines and high-voltage equipment without direct contact reduces the risk of electrical faults,thereby enhancing safety across various applications,including urban energy infrastructure and rural electrification projects. moreover, their design facilitates the maintenance of a stable electrical environment, ensuring that surrounding structures and wildlife remain unharmed by stray currents.

In addition to their primary function of preventing electrical hazards, standoff insulators contribute to the longevity and reliability of electrical installations. Their composition is engineered to withstand environmental challenges such as temperature fluctuations, moisture, and UV exposure, thus minimizing deterioration over time. To better illustrate the various advantages of standoff insulators, consider the following benefits:

| Advantage | Description |

|---|---|

| Electrical Isolation | Prevents direct contact with live wires, reducing shock risk. |

| Structural Support | Stabilizes overhead lines, ensuring proper alignment and function. |

| Weather Resistance | Built to endure extreme weather conditions, enhancing durability. |

| Wildlife Protection | Reduces the likelihood of animal interference with electrical systems. |

Q&A

Q&A: Understanding Standoff Insulators - Key to Electrical Safety

Q1: What exactly are standoff insulators, and what role do they play in electrical systems?

A1: Standoff insulators are components used in electrical systems to provide support and electrical insulation between conductive materials and grounded structures. By maintaining a safe distance between live wires and conductive surfaces, they help prevent electrical arcing, short circuits, and other hazards, playing a key role in enhancing overall electrical safety.

Q2: How do standoff insulators ensure electrical safety?

A2: Standoff insulators act as barriers that protect against direct electrical contact. They prevent the buildup of dangerous voltages on equipment and structures, and their specific design helps to avoid electrical discharges. By keeping wires insulated and separated from each other and from the ground, they significantly reduce the risk of electrical faults.

Q3: What materials are commonly used in the manufacturing of standoff insulators?

A3: Standoff insulators are typically made from high-strength materials such as porcelain, glass, or various types of synthetic polymers.These materials are selected for their excellent insulation properties, durability under various environmental conditions, and resistance to electrical stress, ensuring they perform effectively in different applications.

Q4: In what applications are standoff insulators most commonly used?

A4: Standoff insulators are widely used in overhead power lines, substations, telecommunications, and various industrial settings. They are crucial in any scenario where electrical isolation is required,particularly in high-voltage environments,helping to protect both equipment and personnel.

Q5: Are there different types of standoff insulators?

A5: Yes,standoff insulators come in various shapes and sizes,designed to accommodate different applications and voltage levels. Common types include pin-type, suspension, and strain insulators, each engineered to meet specific mechanical and electrical requirements for optimal performance.

Q6: How can improper use or failure of standoff insulators lead to electrical hazards?

A6: If standoff insulators are improperly installed,deteriorated,or chosen incorrectly for a specific request,they can fail to provide sufficient insulation or support. This failure can lead to electrical arcing, equipment damage, fires, or electrocution risks. Regular inspections and maintenance are vital to ensure their reliability and safety.

Q7: What should one consider when selecting standoff insulators for a project?

A7: When selecting standoff insulators, it's important to consider factors such as the operating voltage, environmental conditions (like UV exposure and temperature extremes), mechanical load requirements, and compatibility with other materials in the system. Consulting with engineers or industry specialists can help in making informed choices.

Q8: How can understanding standoff insulators contribute to better safety practices?

A8: A solid understanding of standoff insulators empowers individuals and organizations to make safer and more informed decisions regarding electrical installations and maintenance. By prioritizing the selection, installation, and upkeep of these insulators, we can enhance system reliability, prevent accidents, and ultimately protect both people and infrastructure from electrical hazards.Q9: Are there industry standards or regulations governing the use of standoff insulators?

A9: Yes, numerous industry standards and regulations govern the use of standoff insulators, ensuring they meet safety and performance benchmarks. Standards established by organizations like the Institute of Electrical and Electronics Engineers (IEEE) and the American National Standards Institute (ANSI) provide guidelines for manufacturers and users to ensure the safe deployment of these critical components.

By understanding standoff insulators and their significance in electrical safety, individuals can promote safer practices in the design, installation, and maintenance of electrical systems.

Closing Remarks

the importance of standoff insulators in ensuring electrical safety cannot be overstated. These unassuming yet essential components form the backbone of reliable electrical infrastructure, bridging the gap between functionality and safety. By maintaining appropriate clearances and enhancing insulation, standoff insulators play a vital role in preventing electrical faults and accidents. As we continue to innovate and expand our electrical systems,understanding and implementing these insulators will remain paramount.

Investing time in learning about their design, application, and maintenance not only fortifies our existing frameworks but also paves the way for future advancements in safety protocols. So, whether you’re a professional in the field or simply an interested reader, taking a closer look at these key players in electrical engineering will empower you to appreciate the complexities of safety in our increasingly electrified world. As we navigate the ever-evolving landscape of technology, let us remember that a strong foundation in the basics, like standoff insulators, is essential for building a safer tomorrow.