In the intricate tapestry of power systems, where electricity flows seamlessly to energize our homes, businesses, and infrastructure, the unsung heroes of design frequently enough go unnoticed. Among these vital components are standoff insulators—critical elements that silently safeguard the delicate balance between safety and functionality in electrical networks. Nestled between the towering poles and sprawling transmission lines, standoff insulators serve as both protectors and facilitators, ensuring that high-voltage currents are guided with precision while preventing unwanted discharges. As we delve into the world of standoff insulators, we will uncover their design, materials, and the pivotal role they play in maintaining the integrity of power systems. Join us on this journey to understand how these essential components contribute to the reliability and efficiency of the electrical grid,allowing us to power our lives with confidence.

Table of Contents

- The Role of Standoff Insulators in Electrical Safety and System Reliability

- Key Design Features of Standoff Insulators and Their Impact on Performance

- Guidelines for Selecting the Right Standoff Insulators for Your Power System

- Maintenance Practices to Extend the Life of Standoff Insulators in Power infrastructure

- Q&A

- In Conclusion

The Role of Standoff Insulators in Electrical Safety and System Reliability

Standoff insulators play a pivotal role in ensuring both electrical safety and the reliability of power systems. By providing separation between energized components and their supporting structures, these insulators help prevent electrical arcing and short circuits.They are designed to withstand environmental factors such as moisture, grime, and temperature fluctuations, which can compromise their effectiveness. Some significant advantages of using standoff insulators include:

- Enhanced Safety: Standoff insulators decrease the risk of accidental contact with live wires.

- System Longevity: Proper insulation reduces wear and tear on equipment, prolonging service life.

- improved Performance: Effective insulation minimizes energy loss and enhances system efficiency.

Moreover, the materials and designs of standoff insulators are carefully analyzed to ensure optimal performance under diverse conditions. Varieties such as ceramic, polymer, and glass insulators cater to different applications, each offering unique benefits. Below is a simple comparison of the three materials typically used for standoff insulators:

| Material | Advantages | Common Use Cases |

|---|---|---|

| Ceramic | Durability, high thermal resistance | transmission lines, substations |

| Polymer | Lightweight, resistant to vandalism | Urban areas, distribution networks |

| Glass | Transparency for easy inspection, chemical resistance | Historical sites, high-stress applications |

Key Design Features of Standoff Insulators and Their Impact on Performance

Standoff insulators are specifically engineered with several key design features that substantially enhance their effectiveness within power systems. Among these features are material selection,geometry,and electrical performance characteristics. The choice of materials, such as high-quality ceramics or polymers, directly influences the insulators' ability to withstand environmental stresses and resist electrical discharges. Additionally, the geometry of the insulators, including their diameter and length, plays a crucial role in ensuring adequate spacing between conductive parts, which prevents electrical arcing and enhances safety.

Furthermore, the surface characteristics of standoff insulators foster better performance in various settings. These include properties like hydrophobicity and anti-fog features, which minimize contamination and water accumulation, reducing the risk of flashovers. To illustrate their impact, the following table summarizes significant design features and their corresponding effects on performance:

| Design Feature | Impact on Performance |

|---|---|

| Material Quality | Increased durability and lifespan |

| Geometry | Enhanced electrical clearance and stability |

| Surface Treatment | Reduced contamination and improved electrical reliability |

Guidelines for Selecting the Right Standoff Insulators for Your Power System

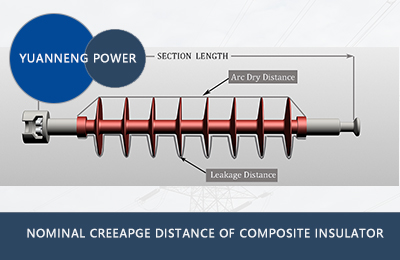

Choosing the appropriate standoff insulators for your power system involves a multitude of factors. Material is paramount; options like porcelain, glass, and polymer each offer unique properties that suit different environmental conditions and voltage requirements. it's crucial to consider mechanical strength, as these insulators must withstand not only electrical stress but also environmental pressures such as wind and ice loading. additionally, evaluating the creepage distance and tracking resistance of the insulators will help ensure safety and longevity, especially in areas prone to contamination.

When reviewing options, consult the following aspects to make an informed decision:

- Voltage Rating: Ensure insulators are rated for the voltages of your submission.

- Environmental Conditions: Assess exposure to factors like moisture, pollution, and temperature extremes.

- Regulatory Standards: match the insulators with applicable safety and performance standards.

- Installation Requirements: Consider ease of installation and compatibility with existing structures.

| Material | Benefits | Drawbacks |

|---|---|---|

| Porcelain | High strength, good thermal stability | Heavy, fragile |

| Glass | Clear, allows for condition monitoring | Breakable, heavier than polymers |

| Polymer | Lightweight, high resistance to tracking | Susceptible to UV degradation |

Maintenance Practices to extend the Life of Standoff Insulators in Power Infrastructure

To ensure the longevity of standoff insulators in power infrastructure, implementing consistent and thorough maintenance practices is crucial. Regular visual inspections should be conducted to check for signs of wear,cracking,or environmental damage. this can prevent minor issues from escalating into major failures. Additionally, seasonal cleaning is critically important, as pollutants and dirt can compromise the insulator's performance.Using a gentle wash with water and mild detergent can restore the insulator's functionality without causing harm. Here are some key maintenance practices to incorporate:

- Routine Inspections: Schedule inspections bi-annually to monitor the condition.

- Cleaning: Clean with appropriate methods to avoid abrasive damage.

- Immediate Repairs: Address any identified issues promptly to mitigate risk.

Moreover, the environment surrounding these insulators should also be regularly assessed. Factors such as vegetation and wildlife can pose threats, so maintaining a clear area around each insulator is essential. Implementing a systematic approach to monitor the environmental conditions can also help in identifying potential hazards early on. The following table summarizes the environmental factors and their potential impacts:

| Environmental Factor | Potential Impact |

|---|---|

| Vegetation Overgrowth | Increased risk of short-circuits and damage. |

| Dust and Debris Accumulation | May reduce insulating effectiveness. |

| Wildlife Activity | Physical damage or contamination. |

Q&A

Q&A: Understanding Standoff Insulators – Essential Components in Power Systems

Q1: What are standoff insulators, and where are they commonly used?

A1: Standoff insulators are essential electrical components used to support and insulate overhead conductors and electrical equipment from surrounding structures. They create a physical distance, preventing direct contact and ensuring safety. You’ll typically find these insulators in high-voltage power lines,substations,and various electrical installations where power transmission and distribution occur.

Q2: How do standoff insulators function?

A2: Standoff insulators serve two primary functions: they provide mechanical support and electrical insulation. By keeping conductors separated from poles,towers,and other surfaces,they reduce the risk of electrical shorts and faults. The insulating material, frequently enough made from ceramics or polymers, resists electrical breakdown, thereby ensuring the continuous and safe operation of power systems.

Q3: What materials are standoff insulators made from, and why are these materials significant?

A3: standoff insulators are primarily made from materials like porcelain, glass, and polymer composites. Ceramics, for instance, offer excellent mechanical strength and resist weather extremes, making them ideal for outdoor applications. Polymers, conversely, tend to be lighter and can be engineered to have enhanced hydrophobic properties, reducing contamination and facilitating maintenance. Each material choice depends on the specific needs of the power system, such as voltage level and environmental conditions.

Q4: Why are standoff insulators important in power systems?

A4: Standoff insulators play a crucial role in ensuring the reliability and safety of power systems. They minimize the risk of electrical failures that could lead to outages or accidents. By maintaining proper distances between conductors and structures, they help to prevent arcing and insulate against excessive electrical voltages. Ultimately, these insulators contribute to the overall efficiency of energy transmission, which is vital for modern society.

Q5: what factors should be considered when selecting standoff insulators for a project?

A5: When selecting standoff insulators, several factors must be considered, such as voltage rating, ambient environmental conditions (like humidity and temperature), mechanical load requirements, and the specific electrical application. Additionally, regulatory compliance, as well as maintenance needs and lifespan of the material, are vital to ensure that the insulators perform efficiently throughout their intended service period.

Q6: Can you discuss the impact of weather on standoff insulators?

A6: Weather can significantly impact the performance of standoff insulators. Factors like moisture, ice, and extreme temperatures can affect the insulating materials and potentially lead to tracking or flashover. As an example, heavy rain or snow accumulation can reduce the insulator's effectiveness. It’s vital to choose materials designed for specific climatic conditions to ensure durability and reliable insulation, which in turn protects the entire power system from failures due to environmental stress.

Q7: Are there any emerging technologies or innovations related to standoff insulators?

A7: Yes,there are ongoing innovations in the field of standoff insulators. Advances in materials science have led to the progress of improved polymer insulators with better resistance to environmental degradation and electrical tracking. Smart insulator systems are also evolving, incorporating sensors that can monitor conditions in real time. These technologies aim to enhance preventative maintenance, ultimately increasing the operational life of power systems and reducing outage risks.

Q8: How can proper maintenance of standoff insulators contribute to power system reliability?

A8: Regular maintenance of standoff insulators is crucial for identifying wear, damage, or contamination that can hinder performance. Inspections and cleaning can help prevent issues like tracking or leakage currents that could lead to failures. By ensuring that insulators maintain their integrity over time, utilities can significantly enhance the overall reliability of the power system, increase uptime, and mitigate safety hazards associated with electrical faults.

This Q&A provides a comprehensive overview of standoff insulators and their meaning in power systems, encapsulating their functions, materials, and importance in maintaining the modern electrical infrastructure.

In conclusion

standoff insulators play an indispensable role in the intricate web of power systems, serving as the silent guardians that bridge the gap between power transmission and safety. Their unique design and robust functionality ensure that electricity flows seamlessly while protecting both the infrastructure and the environment.As we continue to innovate and expand our energy networks, the importance of understanding these essential components cannot be overstated. Whether you are a seasoned engineer,a student of electrical systems,or simply a curious mind,appreciating the intricacies of standoff insulators enriches your understanding of how we harness and deliver power in our modern world. As we move forward into a future powered by renewable energy and smart technologies, let us not forget the essential elements that sustain our electrical infrastructure, transforming energy into the lifeblood of our society.