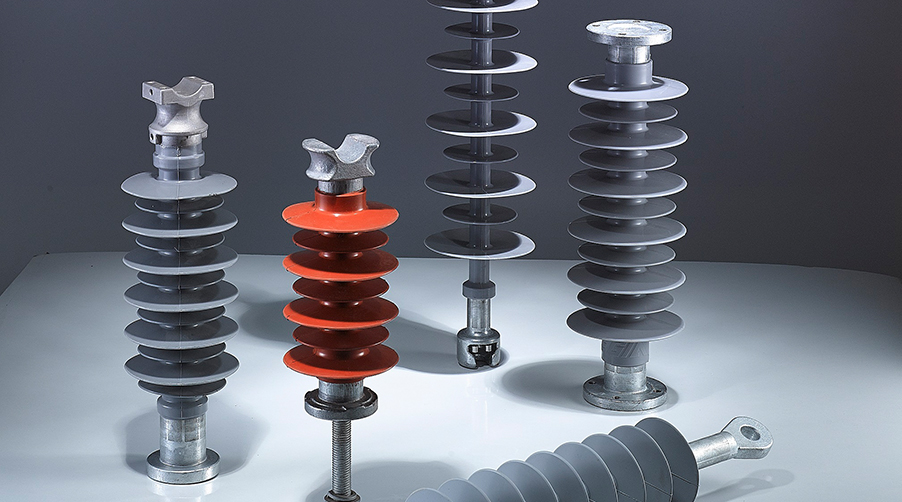

Insulator is used to suspend conductors and keep them insulated from towers and the earth, it is an important part of transmission and distribution lines.

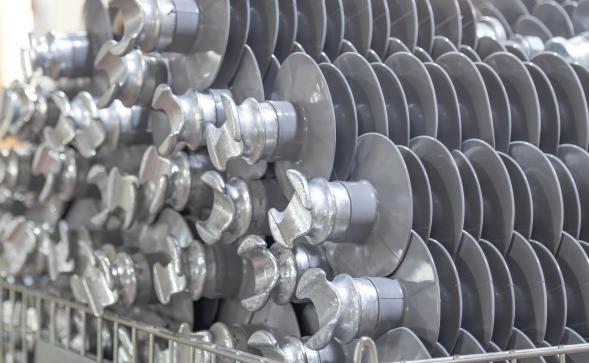

Yuanneng focus on silicone rubber insulator over 15 years, we adopt advanced injection and high-temperature vulcanization craft to keep the mold tightly closed without gaps. We use high accuracy and large force crimping machines to guarantee the end metal fittings will not fall off during its standard withstand tension load.

With rich experience, we have a professional team that can design, produce and optimize various insulators. Our insulator has feature of good insulation properties and sufficient mechanical performance,to be a good choice to ensure the reliability and safety of the power system.

Polymer insulators are widely used in transmission lines, substations, power equipment and other fields.In transmission lines, insulators are often used in suspension lines and spanning lines to bear the weight of power lines and support power lines; in substations, insulators are mainly used for the insulation and support of high-voltage cables to ensure the safe operation of power equipment. It can protect electrical equipment from electric shock accidents and protect the lives of workers. At the same time, it also prevents electrical equipment from being damaged or damaged due to ground faults, to improve the reliability of power systems.

Appearance Inspection

The metal accessories should conform to the drawings, the color of the insulator should be close to that specified on the drawings, and there should be no illegal defects on the surface of the insulator.The name of the manufacturer, year of manufacture and rated mechanical load should be clearly and firmly marked on the insulator.

1min Power Frequency Withstand Voltage Test

The withstand voltage test is to evaluate the performance of insulators under high voltage. This test gradually increases the voltage and observes the performance of the insulator under high voltage to evaluate its voltage withstand capability. The insulator should be able to withstand the required voltage without breakdown or flashover after 1 minute.

Mechanical Load Tensile/Bend Test

The insulator should withstand 50% of the rated mechanical load for 10 seconds at least without damage or deformation.

Galvanized Layer Inspection: ISO 1461:2009

Avergae minimum coating thickness will be ≥85μm, 600g/m2

Creepage Distance Measurement

The minimum nominal creepage distance should comply with the pollution classification requirements.

You need to consider the type of polymer insulator you need, such as what function you need and where you want it to be installed. Yuanneng provides a variety of insulators for your chosen, including polymer dead-end insulators, long rod insulators, pin insulators, cross-arm insulators, polymer line post insulators, windproof silicone rubber insulators, etc.

You need to note basic electrical performance requirements, including rated voltage, lightning and power frequency withstand voltage, required creepage distance, the structural height that the design institute reserves for the insulator part when designing power line, and the tensile load or bending load etc.

Another thing need to be considered is to know about international standards, like IEC 61109, IEC 61952, ANSI C29.13, ANSI C29.17, etc. Yuanneng follow the standards in the design, manufacturing, and inspection of the products. We provide you with quality products at reasonable prices. If you need test report for reference, welcome to contact us.

Finally, you need to pay attention to insulator packaging. Overseas orders often have long voyages, especially in LCL delivery, the transportation method will be changed several times. Insulatorare easily deformed under pressure, so a good packaging method is crucial. Yuanneng can provide several different packaging grades, depending on the mode of transport and expected storage conditions. Special packaging arrangements are available upon user request.

Established in 2007, Yuanneng Power lntegrate Production,Development, Salesand Service Together in the Industry of Compositelnsulator, Fuse Cutout, SurgeArrester, Disconnecting Switch etc.

Copyright © Zhejiang Yuanneng Power Technology Co.,Ltd All Rights Reserved. | Privacy Policy