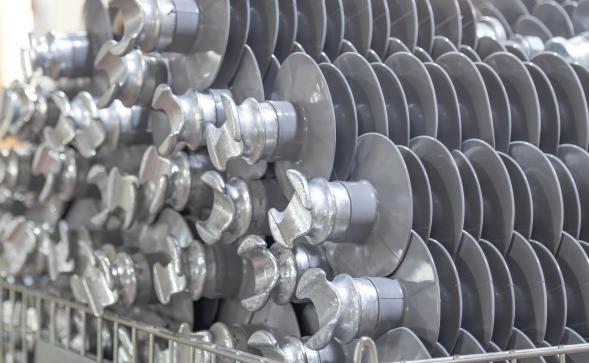

Overhead line fittings plays an important role in connection, fixation, power distribution and protection in the power system, ensuring the normal operation and safety performance of the electric system. They are an integral part of the power system. It comes in many types and has different uses, such as various clamps for installing wires, various hanging rings that make up insulator strings, Various crimped tubes and repair tubes for connecting wires, various types of spacer rods on split wires, etc. In addition, there are various types of wire-staying hardware used in pole towers, as well as the size of the protective wires, which must be coordinated with each other.

Power fittings are widely used in many fields. In the field of power lines, power fittings are used in transmission towers, cable racks and tension towers, and have anti-corrosion, anti-aging and wear resistance, thereby extending the service life of power lines and ensuring the stability and safety of power transmission. In addition, power fittings are also widely used in substations, mainly for connecting, fixing, supporting and protecting various equipment. Specific applications include equipment connection, busbar support and fixing, conductor and insulator connection, grounding and lightning protection. These applications ensure the normal operation and safety and stability of the power system.

Appearance Inspection

Visual inspection of the appearance, size, assembly, mechanical properties, bending properties, zinc layer uniformity, zinc layer thickness, packaging, labeling, and certification of malleable iron castings, forgings, copper-aluminum parts, and cast iron parts. Visual inspection of the product appearance completeness, flexibility, tightness, clarity of product labeling, packaging box specifications, quantity of products packed, and whether there is a certificate of compliance in the box. The inspection results should comply with the corresponding drawings and standard requirements, and the inspection results should be recorded.

Mechanical Performance Testing

Use tensile tests, bending tests and other methods to test whether the mechanical properties of electrical fittings meet the requirements. Products that need to undergo mechanical strength tests should do mechanical property tests on a universal material machine. The test strength should be conducted in accordance with standards. The test results should comply with relevant drawings and standard requirements, and the test results should be recorded.

Electrical Performance Testing

Through methods such as voltage resistance test and conductivity test, the electrical performance of power fittings is tested to see if it meets the standards.

Galvanized Layer Inspection: ISO 1461:2009

Avergae minimum coating thickness will be ≥85μm, 600g/m2

Logo and Packaging Inspection

The factory logo and model should be clear, and the position and font should comply with the drawing and process requirements.

There are many types of hardware, including connecting hardware, suspension wire clamps, tension wire clamps, connection hardware, protection hardware, wire pulling hardware, etc. Please select the appropriate type of hardware according to the line design requirements.

Verification of mechanical load: When designing connection fittings, in order to further expand their interchangeability, the load level is usually simplified to a certain extent, so the mechanical strength of the fittings is determined by the objects they are connected to. During use, insulators with different destructive loads need to use matching fittings.

Configuration principle of connecting fittings: connection by interlocking process. Power fittings need to adapt to different wire types and specifications. When selecting, make sure that the fittings can match the wires, cables and other equipment in the existing power system to ensure its stability and reliability. For example, aluminum wires require aluminum alloy fittings, while steel wires require steel fittings.

The selected hardware combination should meet the geographical environment and natural conditions of the installation site. For example, the crossing should be strengthened; double cross arms should be used at the branch corners; windproof and tension wires should be made. In particular, when large cross-sectional area conductors are used at large corners, reinforced double cross arms should be used.

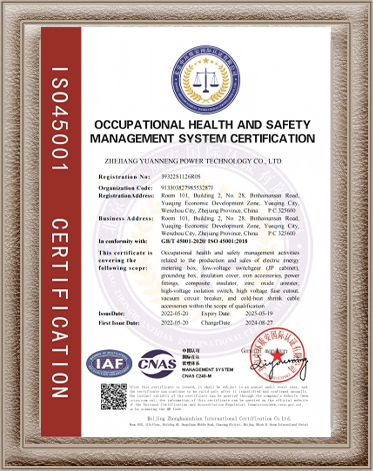

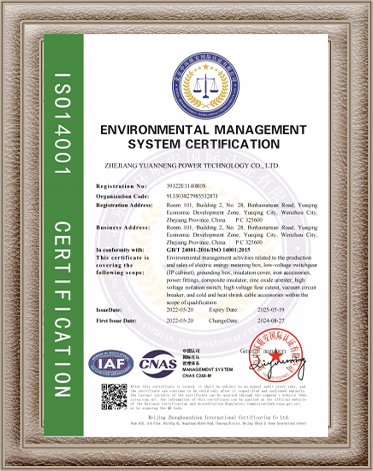

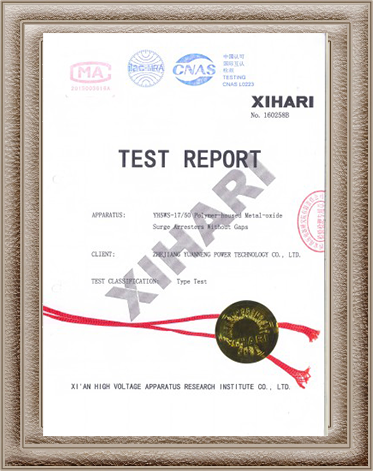

Established in 2007, Yuanneng Power lntegrate Production,Development, Salesand Service Together in the Industry of Compositelnsulator, Fuse Cutout, SurgeArrester, Disconnecting Switch etc.

Copyright © Zhejiang Yuanneng Power Technology Co.,Ltd All Rights Reserved. | Privacy Policy