Polymer Line Post Insulator Manufacturer, No The Middle Man

Custom Solutions for Grid & Renewable Energy

Needs

Lightweight & Corrosion-Resistant – Lasting Performance

500,000 Units Annually – Trusted Global Supply

Capacity

what is a Polymer Line Post Insulator

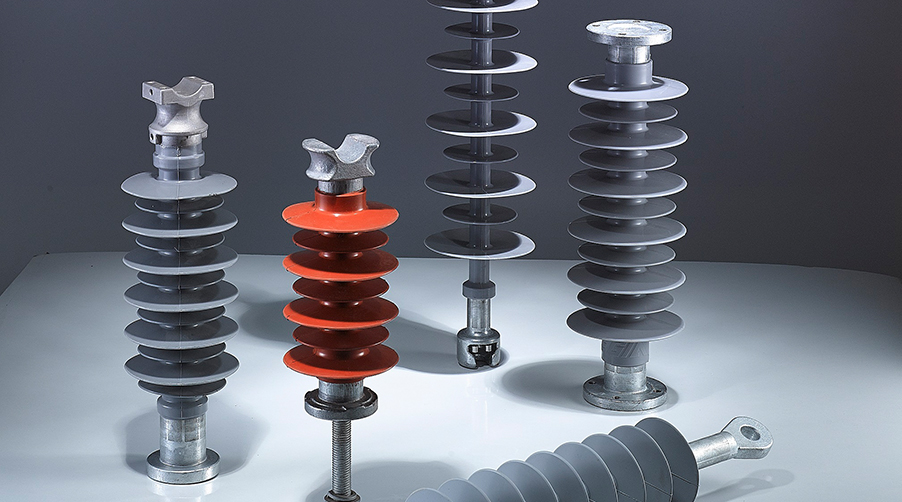

A Polymer Line Post Insulator (also known as a composite line post insulator) is a type of insulator used in overhead power lines, substations, and switchgear, designed to provide mechanical support and electrical insulation in a compact, rigid structure. Unlike suspension insulators (which hang freely), line post insulators are fixed vertically or horizontally to support conductors, busbars, or equipment.

These insulators consist of a high-strength fiberglass rod core encased in weather-resistant polymer housings (e.g., silicone or EPDM rubber sheds), making them lightweight, durable, and resistant to environmental stresses. Polymer line post insulators are an advanced alternative to porcelain, offering superior mechanical strength, pollution resistance, and installation ease. They are widely used in modern power systems, renewable energy, and railway networks where reliability and low maintenance are critical.

Polymer Line Post Insulator Models

We offer a range of high-performance polymer line post insulators designed for

superior electrical insulation and mechanical strength. These insulators provide

excellent resistance to pollution, UV degradation, and other environmental

factors, ensuring long-lasting reliability in demanding applications.

ISO-Certified Production & Full Compliance Type Test Report

Our factory is ISO 9001:2015 certified, ensuring: Standardized Production

Controls, Traceable Quality Management, Consistent Compliance with

International Standards. Product report verifies that the product has passed all

required type tests according to IEC/GB/Industry Standard.

Our Finished Projects

We carefully select different types of polymer line post insulators based on the local

weather conditions and operating environments. This ensures optimal

performance, reliability, and longevity under varying challenges such as pollution,

humidity, high winds, or extreme temperatures.

Trusted by Global Leaders in Power Transmission

Join 1000+ satisfied clients who trust critical infrastructure to our expertise.

Request your project consultation today!

“We've been using your polymer insulators for years, and they’ve never let us

down! Consistent quality, on-time delivery, and great after-sales support. That’s

why we keep coming back.”

"Your insulators outperform others in UV resistance and mechanical strength—our

field tests prove it. Plus, your team always responds quickly to technical requests.

A reliable partner!"

"We tried other suppliers, but none match your combo of durability and service.

Your insulator just work, rain or shine. No surprises, no failures—just peace of

mind."

"It’s not just the quality (which is top-notch), but how you handle issues. Lastminute order changes? Urgent replacements? Your team delivers. That’s why we

stick with you." -

From Start to Finish, We’re By Your Side

Whether you’re just beginning your project or nearing the finish line, count

on us to stand with you—offering guidance, support, and unwavering

commitment. Because your success is our mission, and your story is ours, too.

Together, every step matters.

Components of Polymer Insulator

Core Rod: Made of fibreglass reinforced epoxy

resin for high strength and resistance to

bending. Provides mechanical strength to

withstand tensile and compressive loads.

Housing Material: High-temperature vulcanized

silicone rubber (HTV) or liquid silicone rubber

(LSR) for UV/weather resistance. Protects the

core from environmental factors (UV rays,

moisture, pollution).

Metal Fittings: Forged/ machined galvanized

steel or aluminum alloy (anti-corrosion).

Connects the insulator to the tower/pole and

conductor. Includes ball-and-socket or clevistype connections for flexibility.

silicone rubber (HTV) or liquid silicone rubber

(LSR) for UV/weather resistance. Protects the

core from environmental factors (UV rays,

moisture, pollution).

Metal Fittings: Forged/ machined galvanized

steel or aluminum alloy (anti-corrosion).

Connects the insulator to the tower/pole and

conductor. Includes ball-and-socket or clevistype connections for flexibility.

Forging Metal Fittings

Forged metal fittings are critical for connecting polymer insulators to transmission towers, conductors, and other hardware. These fittings must provide: high mechanical strength, corrosion resistance, reliable electrical connection, and secure sealing.

1. Hot forging (for steel) or cold forging (for aluminum) to form ball sockets, eyes, or flanges.

2. Heat treatment (quenching & tempering) to enhance mechanical strength.

3. Surface treatment: Hot-dip galvanizing (thickness ≥80 μm) or zinc-aluminum coating for corrosion protection.

Crimping Metal Fittings

Crimping metal fittings (sockets, clevises, or balls) onto polymer insulators is a precise mechanical process that ensures long-term durability, high mechanical strength, and moisture sealing. Yuanneng adopt advanced crimping machine, the end fittings are generally squeezed evenly and centripetally from 8 directions, causing slight deformation of the fittings and the mandrel, forming prestress between the fittings and the mandrel, generating friction when subjected to tension, and thus obtaining a stable end connection structure.

Vulcanization/Injection Molding

Injection molding is a key manufacturing process for sheds (housing) in polymer insulators, ensuring weather resistance, electrical insulation, and mechanical durability. Yuanneng adot the advanaced inject machine, place the core rod into the silicone rubber injection mold, inject the rubber, and discharge the gas generated in the process; control the temperature to fully vulcanize the silicone rubber material. After vulcanization, cross-linking occurs between the silicone rubber macromolecules to improve the aging resistance of the material.

Quality Assurance & Testing Process

We conduct 100% mechanical testing on every polymer insulator, including tensile strength and bending resistance, ensuring top-tier durability and performance. Before shipment, all products undergo strict random inspections, covering: Dimensions & Appearance, Electrical Performance, Accessories Accuracy, etc. Only fully compliant products are approved for delivery, backed by a Final Inspection Report. Quality isn’t optional—it’s guaranteed.

Line Post Insulator Delivery Photos

Witness the journey of our premium polymer line post insulators, from the

manufacturing facility to the delivery truck. Trace their path from production to

transport – experience the transparency and quality that defines our process.

Explore Now!

Who is Yuanneng?

A leading manufacturer and solution provider of high-voltage transmission

and distribution (T&D) products, specializing in composite insulators, drop-out

fuses, zinc oxide surge arresters, and disconnectors.

Get A Customized Solution

Request a customized quote today – our polymer line post insulators offer superior

leakage resistance, mechanical strength, and lifespan for utility & industrial

applications.

Choose A Polymer Line Post Insulator With Easy

01. Submit Your Requirement

Tell us your voltage class, creepage distance, and mounting needs – we’ll match the perfect polymer insulator.

02. Receive Tailored Solutions

Get technical drawings, and a competitive quote within 24 hours.

03. Confirm & Start Production

Approve the final design, and we’ll launch mass production with 100% quality assurance.

Copyright © Zhejiang Yuanneng Power Technology Co.,Ltd All Rights Reserved. | Privacy Policy