What Are Composite Polymer Insulators and Where Are They Used?

Power lines carry electricity, but they need protection. Composite polymer insulators keep electricity safe and prevent dangerous leaks. They are the unseen heroes of our power grids.

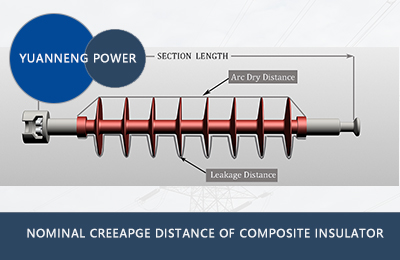

Composite polymer insulators are made of silicone rubber and fiberglass rods, offering better pollution resistance and lighter weight than traditional porcelain insulators. They are widely used in power transmission, distribution networks, and rail transit systems.

Now, let’s dive deeper. Why are these insulators needed? What makes them better than old options? We’ll break it all down below.

Why Do We Need Insulators?

Electricity is powerful, but uncontrolled, it can be dangerous. Insulators keep electricity where it should be—inside the wires—stopping leaks and accidents.

Insulators prevent electricity from escaping wires, avoiding short circuits, fires, and power losses. They also protect equipment and people from accidental shocks.

Without insulators, power lines would be unsafe. Here’s why they matter:

How Do Insulators Work?

- Block Current Flow: Made of non-conductive materials, they stop electricity from jumping off wires.

- Support Wires Structurally: They hold power lines in place, resisting wind, rain, and storms.

- Prevent Flashovers: They keep high-voltage lines from sparking when wet or dirty.

| Function | Importance |

|---|---|

| Electrical Isolation | Stops power leaks |

| Mechanical Strength | Handles heavy wire tension |

| Weather Resistance | Works in storms and pollution |

Composite polymer insulators excel in all these areas, making modern grids reliable.

What Are the Advantages of Polymer Insulators?

Old porcelain insulators are heavy and fragile. Polymer insulators are lighter, tougher, and resist pollution better—key for modern power needs.

Polymer insulators are lightweight, resistant to pollution flashovers, and last longer than porcelain. Their silicone rubber sheds water and dirt, preventing failures.

Here’s why utilities and engineers prefer them:

Key Benefits

-

Lighter Weight

- Easier to transport and install, cutting labor costs.

- Less stress on towers and poles.

-

Pollution Resistance

- Silicone rubber sheds water and contaminants.

- Performs well in coastal, industrial, or dusty areas.

-

Durability[^1]

- No cracking like porcelain.

- UV-resistant for long-term outdoor use.

| Feature | Polymer Insulator | Porcelain Insulator |

|---|---|---|

| Weight | Light | Heavy |

| Pollution Resistance[^2] | High | Low |

| Impact Resistance | High | Low (breaks easily) |

These traits make them ideal for harsh environments.

What Are the Disadvantages of Polymer Insulators?

No product is perfect. Polymer insulators have a few drawbacks—mostly related to aging and cost.

Polymer insulators degrade over time from UV exposure and chemical reactions. They also cost more upfront than porcelain, though lifetime savings offset this.

Let’s explore the challenges:

Main Weaknesses

-

- Sunlight slowly breaks down silicone rubber.

- Modern additives mitigate this, but it’s still a concern.

-

Higher Initial Cost

- More expensive than porcelain upfront.

- But lower maintenance balances costs long-term.

| Issue | Impact | Solution |

|---|---|---|

| UV Degradation | Reduced hydrophobicity | UV-stabilized rubber |

| Cost | Higher purchase price | Saved maintenance costs |

For most applications, the pros outweigh the cons.

What Are the Different Types of Composite Insulators?

Not all polymer insulators are the same. Different designs serve different voltages and environments.

Common types include suspension, line post, and station insulators, each suited for specific tasks like supporting transmission lines or isolating substation equipment.

Here’s a breakdown:

Types and Uses

-

Suspension Insulators

- Hang vertically from transmission towers.

- Handle high voltages (69kV+).

-

Line Post Insulators

- Mount horizontally on distribution poles.

- Used in crowded urban grids.

-

Station Insulators

- Isolate equipment in substations.

- Shorter but handle extreme currents.

| Type | Voltage | Application |

|---|---|---|

| Suspension | High (≥69kV) | Transmission lines |

| Line Post | Medium (11kV-33kV) | Distribution poles |

| Station | All levels | Substations |

Choosing the right type ensures performance and safety.

What Is the Difference Between Porcelain and Composite Insulators?

Porcelain was the standard for decades. Now, composites are taking over. Here’s how they compare.

Porcelain insulators are heavy, fragile, and prone to pollution failures. Composite insulators are lightweight, durable, and self-cleaning, making them better for modern grids.

The key differences:

Side-by-Side Comparison

-

Material

- Porcelain: Ceramic, brittle.

- Composite: Silicone rubber + fiberglass, flexible.

-

Performance

- Porcelain cracks under stress; composite bends.

- Composite sheds pollution; porcelain collects it.

-

Cost

- Porcelain: Cheap upfront, expensive maintenance.

- Composite: Higher initial cost, lower lifetime cost.

| Factor | Porcelain | Composite |

|---|---|---|

| Weight | Heavy | Light |

| Breakage Risk | High (cracks) | Low (flexes) |

| Pollution | Needs cleaning | Self-cleaning |

Utilities are switching to composites for reliability and savings.

Conclusion

Composite polymer insulators outperform porcelain in weight, pollution resistance, and durability. They are the future of safe, efficient power transmission worldwide.