In an era where electrical infrastructure underpins modern life, the quest for safety and reliability remains paramount. Enter composite polymer insulators—an innovative solution that stands at the intersection of engineering excellence and cutting-edge materials science. These unsung heroes of the electrical grid not only promise enhanced performance but also offer meaningful advances in safety, longevity, and resilience against the elements. As we delve into the world of composite polymer insulators, we will explore the technological innovations that have transformed traditional insulating materials, the rigorous safety standards that govern their use, and the vital role they play in safeguarding our increasingly electrified environments.Join us on this journey to understand how these advanced insulators are paving the way for a more secure and efficient future in electrical transmission and distribution.

Table of Contents

- Exploring the Composition and Structure of Polymer Insulators

- advancements in Durability and Weather Resistance

- Enhancing Safety Standards through Innovative Testing Methods

- Best practices for Installation and Maintenance of Composite Insulators

- Q&A

- To Conclude

Exploring the Composition and Structure of Polymer Insulators

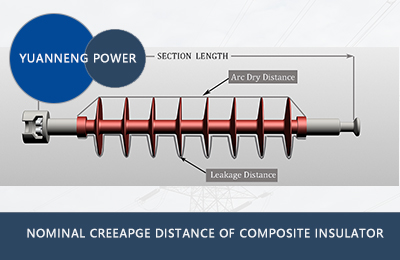

The intricate composition of polymer insulators is a fusion of advanced materials designed to enhance performance while ensuring longevity. These insulators are primarily made from a combination of high-quality polymeric materials, such as silicone rubber and ethylene propylene diene monomer (EPDM). The selection of these materials contributes to their excellent electrical insulation properties and outstanding resistance to environmental stressors.The multilayer structure typically consists of an outer weather-resistant shell, a core that provides mechanical support, and an inner layer that excels at insulating. This layered architecture allows for the in-depth tailoring of properties that meet specific utility needs, whether it's contaminant resistance or hydrophobic characteristics.

Moreover, recent innovations in the manufacturing processes of polymer insulators have introduced sophisticated methods that enhance their overall structure. Techniques like electrospinning and injection molding enable the precise control of material distribution, resulting in greater durability and reliability. With advancements in nanotechnology, the incorporation of nanofillers has shown promising enhancements in mechanical and thermal performance, pushing the limits of what polymer insulators can achieve. Below is a comparison of different polymer insulators utilized in electrical applications, highlighting key attributes:

| Type | Material | Key Benefits |

|---|---|---|

| Silicone Rubber Insulator | Silicone-based | Excellent weathering resistance, high voltage tolerance |

| EPDM Insulator | EPDM composite | Good thermal stability, strong mechanical strength |

| Nano-enhanced Insulator | Polyester with nanofillers | Enhanced durability, improved electrical performance |

Advancements in Durability and Weather Resistance

The latest innovations in composite polymer insulators have considerably enhanced their durability and weather resistance, making them an indispensable choice for utility companies. these advancements are attributed to the improved materials and manufacturing processes that have emerged in recent years. Key features contributing to their robust performance include:

- UV Resistance: Advanced formulations help insulators resist degradation from ultraviolet radiation, prolonging their lifespan.

- Hydrophobic Properties: The surface treatments applied to composite materials repel water, preventing contamination and enhancing electrical performance in wet conditions.

- Temperature Stability: New composites maintain their structural integrity across a wide temperature range, ensuring reliability under extreme environmental conditions.

Furthermore, manufacturers are implementing innovative design strategies that prioritize both functionality and resilience. The integration of nanotechnology and specialized coatings is not only fortifying insulators against harsh climates but also improving their overall aesthetic appeal. A brief overview of their key performance metrics is outlined in the table below:

| Feature | Description |

|---|---|

| Corrosion Resistance | Protects against corrosion caused by pollutants and environmental factors. |

| Mechanical Strength | Superior tensile strength preventing physical damage during installation and service. |

| Shock Resistance | Ability to withstand high electrical surges without failure. |

Enhancing Safety Standards through Innovative Testing Methods

In the quest for improved safety, the adoption of cutting-edge testing methods plays a crucial role, particularly in the field of composite polymer insulators. Traditional testing ofen fell short in simulating real-world conditions, which sometimes lead to undetected vulnerabilities. However, innovative approaches like dynamic load testing and non-destructive evaluation (NDE) are now revolutionizing safety assessments. These methods allow engineers to accurately gauge the insulators' performance under various stress scenarios, providing critical insights into their durability and reliability.

moreover, the integration of digital technology enhances the monitoring and analysis processes, making safety evaluations more comprehensive. Techniques such as thermal imaging and acoustic sensing are employed to identify potential flaws before they escalate into safety hazards. This proactive approach not only extends the lifespan of the insulators but also boosts the confidence of operators in their infrastructure. To illustrate the impact of these advancements, consider the following table that highlights key testing methods and their respective benefits:

| Testing Method | Benefits |

|---|---|

| Dynamic Load Testing | Simulates real-world stress conditions |

| Non-Destructive Evaluation | Identifies flaws without damaging components |

| thermal Imaging | Detects overheating and potential failures |

| Acoustic Sensing | Monitors sound waves to locate defects |

Best Practices for Installation and Maintenance of Composite Insulators

To ensure the longevity and reliability of composite insulators, adhering to best practices during installation is paramount.Proper handling is crucial; avoid dropping or rough handling which can create micro-cracks. When installing, maintain a clean environment to prevent contamination from dirt or debris. It's also vital to adhere to the specific manufacturer guidelines regarding torque settings and alignment to avoid undue stress on the insulator. Always inspect the mounting hardware for corrosion or damage before installation, as compromised components can lead to failure.

Regular maintenance and inspection are key to maximizing the performance of composite insulators.Establish a routine inspection schedule to assess for signs of wear, such as surface erosion or tracking paths.During inspections, consider the following essential checks:

- Visual inspection: Look for cracks, discoloration, or any physical damage.

- Electrical testing: Conduct insulation resistance tests to ensure functionality.

- Cleaning: Keep insulators free from contaminants that can compromise performance, especially in polluted environments.

Additionally, using a maintenance log can significantly enhance the tracking of inspections and repairs, thereby improving reliability. See the table below for a sample maintenance schedule that can help in organizing tasks effectively:

| Inspection Type | Frequency | Notes |

|---|---|---|

| Visual Inspection | Monthly | Look for signs of physical damage or wear. |

| Electrical Testing | Quarterly | Conduct insulation resistance tests. |

| Cleaning | Bi-Annually | Remove contaminants as part of routine maintenance. |

Q&A

Q&A: Understanding Composite Polymer Insulators – Innovations in Safety

Q1: What are composite polymer insulators, and how do they differ from traditional insulators?

A1: Composite polymer insulators are advanced electrical insulation systems made from a combination of organic and inorganic materials. Unlike traditional porcelain or glass insulators, which are rigid and breakable, composite insulators are lightweight and resilient. They possess higher resistance to environmental stressors such as UV radiation, pollution, and moisture, making them an increasingly popular choice in various applications.

Q2: what are the key benefits of using composite polymer insulators?

A2: One of the primary benefits of composite polymer insulators is their superior performance in challenging conditions. Their adaptability allows them to withstand extreme weather without compromising safety. Moreover, they are less prone to damage from physical impacts compared to traditional insulators. Their hydrophobic surface properties help maintain electrical reliability, reducing the risk of flashovers due to contamination or moisture.

Q3: How have composite polymer insulators contributed to safety innovations in the electrical industry?

A3: Thanks to their durability and reliability, composite polymer insulators significantly enhance safety in electrical applications. They minimize the risk of electrical outages and failures caused by environmental factors. Additionally, their lightweight nature simplifies installation and maintenance, reducing the potential for workplace accidents. Innovations such as smart monitoring technologies integrated into these insulators enable real-time assessment of their condition, allowing for proactive maintenance and enhanced safety measures.

Q4: Are there any environmental considerations associated with composite polymer insulators?

A4: Yes, while composite polymer insulators are generally more durable and can offer a longer lifespan compared to traditional materials, there are environmental considerations regarding their production and disposal. Efforts are ongoing to improve the recyclability of these materials, and researchers are actively exploring bio-based polymers that may reduce environmental impact. The goal is to create a enduring lifecycle that aligns with modern environmental standards.

Q5: What future innovations can we expect in the field of composite polymer insulators?

A5: The future of composite polymer insulators is poised for exciting advancements. Researchers are exploring the integration of nanotechnology to enhance their insulating properties and mechanical strength. Additionally, the incorporation of smart features, such as self-cleaning surfaces and integrated sensors for monitoring electrical performance, is on the horizon. These innovations aim to further improve safety, reliability, and efficiency, transforming the way we approach electrical insulation in the coming years.

Q6: How can industries transition to using composite polymer insulators effectively?

A6: Transitioning to composite polymer insulators requires a strategic approach. Industries should evaluate their specific insulation needs and assess the operational environments where these insulators will be deployed. Training and education for personnel on the benefits and submission of composite materials are crucial. Collaborating with manufacturers for guidance on installation best practices and long-term maintenance will ensure a smooth integration into existing systems, promoting a safer and more reliable electrical infrastructure.

Q7: In what applications are composite polymer insulators most commonly used?

A7: Composite polymer insulators are widely used in power transmission and distribution systems, particularly in high-voltage and high-pollution areas. They are also found in renewable energy installations like wind farms and solar power plants, where durability and lightweight properties are beneficial. Additionally, they are increasingly utilized in railway electrification and substations, demonstrating their versatility across various segments of the energy sector.

This Q&A serves as your guide to understanding composite polymer insulators, shedding light on their innovative features and the crucial role they play in enhancing safety within the electrical industry.

To Conclude

the evolution of composite polymer insulators marks a significant milestone in the quest for enhanced safety and reliability in electrical infrastructure. As we have explored, these innovative materials not only address the challenges posed by traditional insulators but also pave the way for more resilient and efficient electrical systems. The fusion of cutting-edge materials science with practical engineering has given rise to solutions that are better equipped to withstand the rigors of environmental stressors and operational demands.

As industries and utilities continue to prioritize safety and sustainability,the role of composite polymer insulators will undoubtedly grow more prominent.Embracing these innovations not only means investing in advanced technology but also fostering a safer future for communities and the environment. As we move forward, it remains imperative to keep both the industry’s needs and environmental responsibilities in mind, ensuring that our energy networks are as safe and reliable as they are innovative.

With ongoing research and development, we can anticipate further advancements that will continue to enhance the protective capabilities of these insulators. The journey of understanding composite polymer insulators is one of continuous betterment—a journey that reflects our commitment to a safer, smarter, and more sustainable energy landscape.