What is a composite insulator?

Composite insulator is an insulating device used in power transmission and distribution systems to support and fix power equipment such as conductors and cables. It is composed of insulating materials and metals, usually made of silicone rubber materials, and has high insulation performance.

Definition of nominal creepage distance

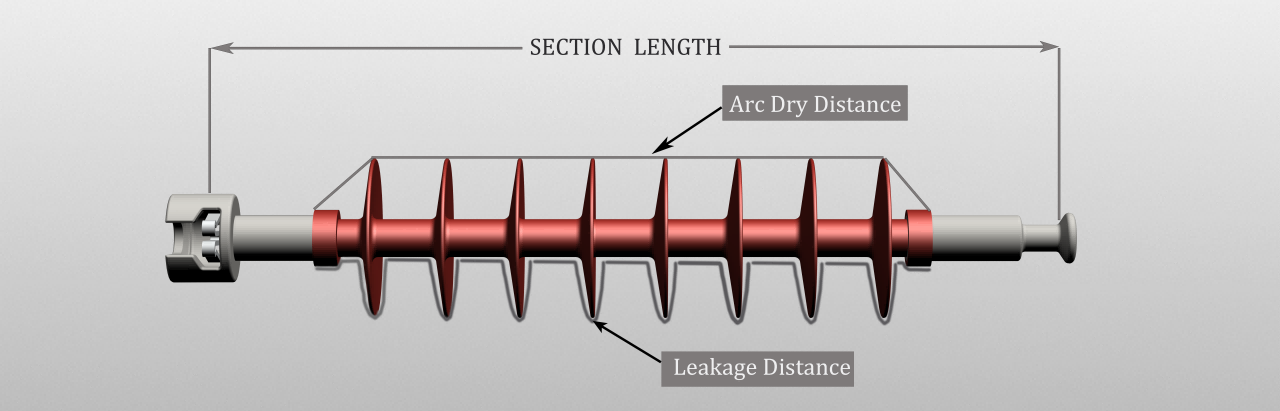

The nominal creepage distance refers to the minimum creepage distance between the two ends of the composite insulator under the rated power frequency voltage. The creepage distance refers to the shortest distance along the surface of the insulator on the surface of the electrical equipment. If the distance between two conductors is less than the creepage distance, it may cause insulator flashover, discharge or short circuit.

Importance of nominal creepage distance of composite insulators

Determination of the nominal creepage distance of composite insulators is one of the key factors to ensure the safe operation of power equipment and systems. If the nominal creepage distance of composite insulators is insufficient or does not meet the requirements, the following problems may occur:

• Insulator flashover: When the voltage between two conductors exceeds the withstand voltage of the insulator, insulator flashover occurs, resulting in arc discharge or electrical equipment failure.

• Degradation of insulation performance: Insufficient nominal creepage distance will lead to degradation of the insulation performance of the insulator, increase the risk of system failure, and may also cause harm to personnel and equipment.

• Short circuit: When the nominal creepage distance of composite insulators is insufficient, a short circuit may occur between the two conductors, resulting in serious consequences such as equipment damage or fire.

Therefore, accurate determination of the nominal creepage distance of composite insulators is crucial for the safe operation of power equipment and the reliability of the system.

Factors Affecting the Nominal Creepage Distance of Composite Insulators

The nominal creepage distance of composite insulators is affected by many factors, mainly including the following aspects:

Insulating materials

The choice of insulating materials has an important influence on the creepage distance of composite insulators. In general, ceramic insulators have a larger creepage distance and can maintain insulation performance under a wide range of operating voltages. Although composite insulators have higher mechanical strength and weather resistance, their creepage distance is relatively small.

Surface contamination degree

The nominal creepage distance of composite insulators is also related to the degree of contamination on the surface of the insulator. When there are pollutants such as dust, salt, and humidity on the surface of the insulator, the insulation performance of the insulator will decrease and the nominal creepage distance will be reduced.

Climate conditions

Climate conditions have a great influence on the creepage distance of composite insulators. For example, in severe climatic conditions such as high humidity, air pollution, and haze, the creepage distance of the insulator may decrease. In a dry and clean environment, its creepage distance may increase.

Method for determining nominal creepage distance of composite insulators

Determining the nominal creepage distance of composite insulators requires insulation performance tests and calculations. Generally speaking, the following methods can be used to determine it:

5.1 Insulation performance test

The insulation performance test is to place the composite insulator in a specific test device, apply the rated power frequency voltage, and observe whether the insulator flashes to determine the nominal creepage distance. The test should be carried out under standard conditions and the test results should be recorded for reference.

5.2 Numerical simulation calculation

In order to simplify the test process and improve efficiency, numerical simulation methods can also be used to calculate the nominal creepage distance of composite insulators. By establishing accurate models and calculation formulas, and considering factors such as insulating materials, surface contamination, and climatic conditions, relatively accurate creepage distance calculation results can be obtained.

Standard for nominal creepage distance of composite insulators

The nominal creepage distance of composite insulators is generally specified by standards set by power industry organizations such as the State Grid Corporation of China. These standards usually classify composite insulators according to different types, application environments, voltage levels and other factors, and specify corresponding creepage distance requirements.

The formulation of standards is intended to ensure the safe operation of power equipment and systems, while taking into account economic factors and actual engineering conditions. Therefore, when designing, selecting and installing composite insulators, the corresponding standard requirements must be followed.

Nominal creepage distance and safety of composite insulators

The nominal creepage distance of composite insulators directly affects the safety of power equipment and systems. Therefore, in engineering design, equipment selection and maintenance, the requirements of nominal creepage distance should be fully considered, and necessary measures should be taken to ensure its safety, including:

• Regularly inspect and clean the surface of insulators to ensure their finish and stain resistance.

• Regularly conduct insulation performance tests to promptly detect and deal with insulators whose creepage distance does not meet the requirements.

• Select appropriate insulating materials and nominal creepage distance to meet the requirements of actual working voltage and environmental conditions.

In conclusion

The nominal creepage distance of composite insulators is an important indicator to ensure the safe operation of power equipment and systems. By correctly selecting insulating materials, managing the degree of surface contamination, considering factors such as climatic conditions, and complying with relevant standard requirements, it is possible to ensure that the nominal creepage distance meets the design and application requirements and improve the reliability and safety of the power system.