Fused cutout, also known as fuse switch, is a protective device used in power systems. It is used in outdoor AC 50HZ or 60HZ, rated voltage distribution lines below 36kV. It plays the role of cutting off the circuit in the event of short circuit faults and overload faults, protecting power equipment and lines from damage.

Principle

The working principle of drop out fuse cutout is based on the thermal protection characteristics of the melting fuse link. When a short circuit fault or overload occurs in the circuit, the current will increase sharply, causing the fuse link to heat up and eventually melt. Once the link melts, the fuse cutout will automatically drop, isolating the circuit from the power system, preventing the fault from continuing to expand, and protecting the safety of equipment and lines.

Fuse Cutout Parts

The drop fuse cutout consists of upper and lower conductive parts, fuse tube, an insulating part and a fixed part.

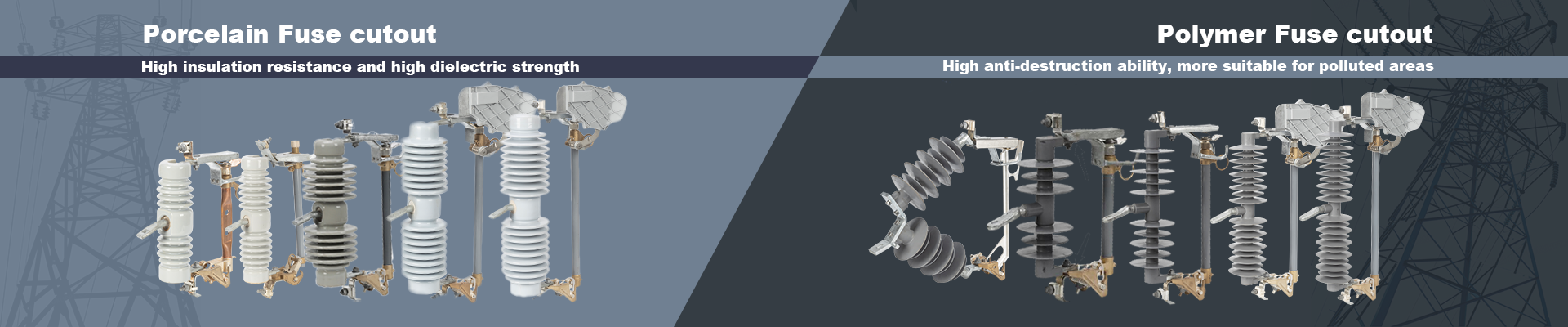

1. Fuse body: Made of insulating material (ceramic and composite material), with good high temperature and voltage resistance

2. Cutout fuse holder: Made of high temperature resistant and low resistance material, used to accommodate fuse wire.

3. Cutout fuse link: A thin wire made of a specific material with a low melting point. When the current exceeds the rated value, it will be heated to a melting state.

4. Fuse base: used to fix the fuse tube and fuse link and provide current contact.

5. Spring: used to support the fuse and maintain the stability of the fuse under normal working conditions

Environmental Conditions for Electrical Fuse Cutout

1. Normal use conditions of the product: ambient temperature is not higher than +40 degrees and not lower than -40 degrees; altitude is not more than 1000m; maximum wind speed is not more than 35m/s; earthquake intensity is not more than 8 degrees.

2. The product is not suitable for the following places: places with danger of combustion or explosion; places with severe vibration or impact; places with conductive, chemical gas and severe salt spray areas.

Installation of Distribution Fuse Cutout

(1)During installation, the fuse should be tightened (so that the fuse is subjected to a tensile force of about 24.5N), otherwise it is easy to cause the contacts to heat up.

(2) The fuse should be installed firmly and reliably on the crossarm (frame) without any shaking or swaying.

(3) The fuse tube should have a downward inclination of 25°±2° to facilitate the fuse tube to fall quickly under its own weight when the fuse blows.

(4) The fuse should be installed on a crossarm (frame) with a vertical distance of not less than 4m from the ground. If installed above the distribution transformer, it should maintain a horizontal distance of more than 0.5m from the outermost contour boundary of the distribution transformer to prevent other accidents caused by the fuse tube falling.

(5) The length of the fuse tube should be adjusted appropriately, requiring that the tongue can hold more than two-thirds of the contact length after closing the switch to avoid malfunction of falling during operation. The fuse tube should not be blocked by the tongue to prevent the fuse tube from falling in time after the fuse blows.

(6) The fuse used must be a standard product from a regular manufacturer and have a certain mechanical strength. Generally, the fuse is required to be able to withstand a tensile force of at least 147N.

(7) When a 10kV drop-out fuse is installed outdoors, the phase-to-phase distance must be greater than 70cm.

Precautions for drop-out fuses

When operating a drop-out fuse, you should also pay attention to the following matters:

1. When replacing a fuse link, you need to select a suitable fuse according to the size of the circuit fault current. If the selected fuse current is too small, it may cause inadequate protection and the circuit cannot be disconnected in time, thus affecting the protection effect; and if the fuse current is too large, it is easy to cause false triggering, causing the circuit to be disconnected during normal operation.

2. When replacing a fuse, be sure to ensure that the circuit is in a power-off state to avoid electric shock or other safety accidents.

3. When replacing a fuse, you need to unscrew the fuse cap first, then remove the original fuse link, and select the corresponding new fuse link according to its size and marking.

4. After replacing the fuse link, you need to install the fuse cap to ensure that the circuit is in normal working condition to avoid safety accidents caused by short circuit or other operating errors.

Advantages of drop-out fuses

• Quick circuit cutoff: Drop out fuses can quickly cut off the circuit when a fault occurs, protecting the safety of equipment and lines.

• High reliability: The fuse body is finely made, the drop device is reasonably designed, the service life is long, and the reliability is high.

• Automatic operation: Drop-out fuses can automatically drop without manual intervention, which improves the convenience of operation.

Application areas

Drop-out fuses are widely used in various power systems, including:

• In power transmission lines: protect transmission lines and transformers from damage.

• In distribution systems: protect equipment and lines in low-voltage distribution systems.

• In industrial power systems: used to protect the safety of industrial equipment and lines.

Conclusion

As a common protection device, drop-out fuses play an important role in power systems through thermal protection characteristics and automatic operation. It can quickly cut off the circuit and protect the safety of equipment and lines. However, it is necessary to pay attention to choosing the right model when using it, and replace the fuse in time to ensure the normal operation of the circuit.