In an age where reliable power distribution is paramount, the unsung heroes of our electrical infrastructure frequently enough stay hidden from sight, functioning quietly in the background. Among these vital components are 15kV fuse cutouts—devices that play an essential role in safeguarding both equipment and personnel. But what exactly are fuse cutouts, and why are thay deemed indispensable in the realm of power safety? This article delves into the intricacies of 15kV fuse cutouts, unraveling their design, functionality, and significance in maintaining the integrity of electrical systems. By illuminating the critical nature of these components,we aim to provide a thorough understanding of how they contribute to the stability and safety of our power networks.

Table of Contents

- The Role of 15kV Fuse Cutouts in Electrical Distribution Systems

- Key Components and Functionality of fuse Cutouts

- Best Practices for Maintenance and Inspection of Fuse Cutouts

- Enhancing Safety Through Proper Installation and Usage Guidelines

- Q&A

- Insights and Conclusions

The Role of 15kV Fuse Cutouts in Electrical Distribution Systems

In today's electrical distribution systems, 15kV fuse cutouts play a crucial role in safeguarding both the infrastructure and the consumers.These devices serve as protective elements, designed to disconnect the electrical circuit in the event of an overload or short circuit. They are strategically placed along overhead distribution lines to ensure that faults can be quickly isolated without affecting the broader network. Key advantages of 15kV fuse cutouts include:

- Safety: By quickly disconnecting faulty sections, they minimize the risk of fire and electrical hazards.

- Reliability: These cutouts contribute to the overall reliability of power distribution, reducing downtime during repairs.

- Cost-Effectiveness: Their simple design and ease of maintenance make them a cost-effective solution for utilities.

Beyond their immediate protective functions,15kV fuse cutouts facilitate operational efficiency by allowing for selective coordination within the electrical system. This means that instead of disrupting the entire circuit, only the affected segments are de-energized, maintaining service to unaffected areas. In a structured grid, this selective approach enhances not just safety but also operational responsiveness. To understand their impact better, here are some essential specifications of 15kV fuse cutouts:

| Specification | value |

|---|---|

| Voltage Rating | 15 kV |

| Interrupting Rating | 10 kA |

| Construction Type | weather-Resistant |

| Fuse Element Material | Alloy or Copper |

Key components and Functionality of Fuse Cutouts

Fuse cutouts play a critical role in the electrical distribution system, designed to protect both the overhead distribution line and the connected equipment from overloads and short circuits. These devices function by using a fuse element that melts when excessive current flows through it, thus breaking the circuit and preventing potential damage. Key components of a fuse cutout include:

- Fuse Element: The heart of the cutout, which melts to interrupt the current.

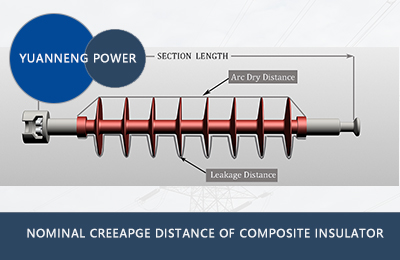

- Insulator: Provides electrical insulation and support, typically made from porcelain or polymer materials.

- Switching Mechanism: Allows for maintenance and the ability to re-establish power when safe to do so.

- Arcing Chamber: Safely extinguishes the arc that forms when current is interrupted.

The functionality of fuse cutouts extends beyond just fault protection; they also facilitate system maintenance and safety. They can be designed to integrate with modern smart grid technologies,providing real-time monitoring and fault detection. additional features often include:

- Remote control Operation: For improved responsiveness in power management.

- Visual Indicators: To aid technicians in identifying operational status.

- weather Resistance: ensures reliable performance in diverse environmental conditions.

| Component | Function |

|---|---|

| Fuse Element | Interrupts current during overloads |

| Insulator | Supports structure and provides insulation |

| Switching Mechanism | Facilitates circuit maintenance |

| Arcing Chamber | Extinguishes arcs safely |

Best practices for Maintenance and Inspection of fuse Cutouts

Regular maintenance and inspection are paramount for ensuring the reliability of fuse cutouts in electrical systems. Technicians shoudl develop a routine schedule to monitor the condition of these devices, focusing on key components such as fuse elements, operating mechanisms, and insulation.A detailed checklist can aid in maintaining a systematic approach to inspections, including:

- Visual inspections for signs of corrosion or damage.

- Checking the operational integrity of the fuses.

- Inspecting the physical connections and mounting hardware for stability.

Moreover, keeping a log of maintenance activities and observations will facilitate better tracking of performance over time.It’s also essential to follow manufacturer guidelines regarding replacement intervals and safety protocols during inspections. The following table highlights some common indicators that might suggest the need for immediate action:

| Indicator | Suggested Action |

|---|---|

| visible physical damage | Replace cutout promptly |

| Frequent fuse operations | Investigate load changes |

| Insulation wear and tear | Consider refurbishing or replacing |

Enhancing Safety Through Proper Installation and Usage Guidelines

Proper installation and adherence to usage guidelines are critical in ensuring the effective operation of 15kV fuse cutouts. When these components are correctly installed, they can considerably reduce the risk of electrical failures and protect both equipment and personnel. Key considerations for installation include:

- choosing the Right Location: Ensure cutouts are installed in areas with adequate airflow and protection from environmental hazards.

- Correct Mounting: Follow manufacturer guidelines for mounting to prevent excessive strain and ensure stability.

- wire Sizing: Use appropriate gauge wiring that aligns with the manufacturer’s specifications to avoid overheating.

- Regular Inspection: Schedule periodic inspections to identify wear and tear early.

Utilizing the cutouts according to established protocols helps in mitigating risks associated with electrical systems. Operators must ensure that they are familiar with safety mechanisms and operating procedures. Important usage guidelines include:

- Training Personnel: Provide comprehensive training for personnel to recognize signs of malfunction.

- Emergency Procedures: Implement clear procedures for emergency situations involving fuse cutouts.

- Load Monitoring: Continuously monitor power loads to prevent overload scenarios that could lead to fuse failure.

- Documentation: Keep detailed records of maintenance and inspections to facilitate accountability and improve future safety measures.

Q&A

Q&A: Understanding 15kV Fuse Cutouts: essential for Power Safety

Q1: What are 15kV fuse cutouts, and where are they typically used?

A: 15kV fuse cutouts are electrical devices that protect power distribution systems by interrupting the circuit in the case of overloads or faults. They are commonly found in outdoor utility applications, such as on power poles or substations, playing a crucial role in the safety and reliability of electrical networks.

Q2: Why is it important to understand how fuse cutouts work?

A: Understanding fuse cutouts is fundamental as they enhance power safety by preventing equipment damage and outages. By knowing how they operate, utility workers and personnel can effectively maintain and troubleshoot the system, reducing risks to both infrastructure and human safety.

Q3: How do 15kV fuse cutouts differ from regular fuses?

A: While both serve to interrupt excessive current, 15kV fuse cutouts are specifically designed for higher voltage applications (up to 15,000 volts). They typically include additional features, such as visual indicators for easier monitoring and operation in outdoor environments, distinguishing them from standard fuses used in lower voltage settings.

Q4: What are the main components of a 15kV fuse cutout?

A: A 15kV fuse cutout generally comprises a fuse element, a housing, a support structure, and an operating mechanism. The fuse element is the key component that melts to open the circuit during fault conditions, while the housing provides protection against environmental elements.

Q5: How does the operation of a fuse cutout contribute to electrical safety?

A: When a fault occurs, the fuse element inside the cutout melts due to excessive current flow, breaking the circuit and preventing further damage to electrical equipment. This speedy interruption minimizes risk not just to the infrastructure, but also to personnel working nearby, ensuring a safer power distribution environment.Q6: What maintenance is required for 15kV fuse cutouts?

A: Regular maintenance is essential for 15kV fuse cutouts to ensure functionality and safety. This includes inspecting the physical condition of the housing, checking for corrosion, testing the fuse elements for integrity, and confirming that the operating mechanism is free of obstructions.Routine maintenance helps to prolong lifespan and enhance reliability.

Q7: Can users replace 15kV fuse cutouts themselves?

A: While some knowledgeable individuals may feel confident replacing a fuse cutout, it is indeed generally advised that such tasks be handled by qualified utility personnel. The high voltage associated with 15kV systems poses serious risks, and professional technicians are trained to manage these hazards safely.

Q8: Are there any advanced features in modern 15kV fuse cutouts?

A: Yes, many modern 15kV fuse cutouts come equipped with smart technology, such as remote monitoring capabilities, which allow for real-time data analysis on the health of the distribution system. These advancements can help utilities respond more quickly to issues, improving overall grid reliability and efficiency.

Q9: How can users identify when a fuse cutout has operated?

A: Many fuse cutouts are designed with a visible fuse indicator that changes color or position when the fuse has operated. This feature allows utility personnel to readily identify which cutouts may require attention, improving response time to outages.

Q10: why should we care about fuse cutouts?

A: fuse cutouts serve as a critical line of defense in electrical safety for utility companies and customers alike. By understanding their function and maintenance needs, we contribute to a more reliable and secure power distribution system, ultimately ensuring safer living and working environments for everyone.

Insights and Conclusions

understanding 15kV fuse cutouts is not just a technical necessity but a vital pillar in the robust infrastructure of electrical safety. These devices stand as silent guardians, ensuring that our power systems operate smoothly and safely, safeguarding both equipment and lives. As we delve deeper into the intricacies of electrical safety, it becomes increasingly clear that knowledge of these components empowers us to make informed decisions, anticipate potential hazards, and contribute to a safer environment.

Whether you are a seasoned professional in the electrical field or a curious newcomer, grasping the significance of fuse cutouts equips you with the tools to appreciate their role in the larger picture of electrical systems. As technology continues to evolve, staying informed about such essential components will be key to adaptation and innovation.Remember, safety is not just a priority; it should be a way of life, woven into the fabric of our everyday practices. As we turn off the last switch on this discussion, may your understanding of power safety shine brightly, illuminating the path forward in our electrified world.