In the vast web of power lines that crisscross our landscapes, an unsung hero quietly performs a vital role, frequently enough overlooked by the hurried gaze of the everyday observer. These are the suspension insulators, the silent guardians of our electrical grid. While they may appear as mere extensions of metal and glass strung between towering pylons, their function is far from mundane. They embody the delicate balance between safety and efficiency, ensuring that the electricity coursing through our infrastructures remains steady and secure. As the silent sentinels of the power transmission network, suspension insulators are engineering marvels that withstand the elements, resist the wear of time, and maintain the unbroken flow of energy we often take for granted. In this article, we will delve into the world of suspension insulators, exploring their intricate designs, the materials that make them resilient, and the critical role they play in keeping our lights on and our devices charged. Join us as we uncover the silent strength behind our electrified lives.

Table of Contents

- Understanding the Role of Suspension Insulators in Power Transmission

- Materials and Innovations: Enhancing the Durability of Insulators

- Maintenance Strategies for Longevity and Reliability in Power Systems

- Environmental Considerations: Balancing Functionality with Sustainability

- Q&A

- Concluding Remarks

Understanding the Role of Suspension Insulators in Power Transmission

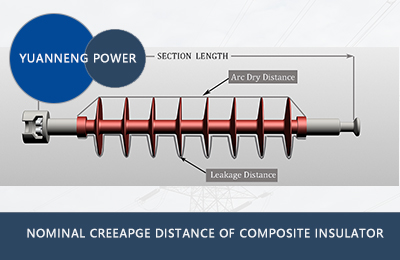

Suspension insulators are critical components in power transmission systems, ensuring the electrification of our cities while maintaining safety and reliability. These insulators serve as a barrier between the live wires and the supporting structures, such as towers and poles. Their primary function is to suspend the conductors while providing electrical insulation. This prevents unwanted electrical discharges that could lead to major outages or hazards.The materials used in these insulators, often ceramic or composite polymers, are chosen for their high dielectric strength and weather resistance, making them extremely effective against environmental challenges.

Moreover, the design of suspension insulators plays an essential role in their performance. They come in various configurations to suit different voltage levels and environmental conditions. Here are a few aspects to consider:

- Mechanical Strength: Insulators must withstand tension from the weight of the conductors and external forces such as wind.

- Electrical Properties: High insulation resistance is critical to prevent leakage currents.

- Aesthetic Integration: some designs are created to blend seamlessly into landscapes, reducing visual impact.

Along with their physical properties, regular maintenance of suspension insulators is vital to ensure long-term reliability. Inspecting for signs of wear, contamination, or degradation allows for timely interventions, preventing potential failures. Organizations often employ specialized equipment to monitor the health of these insulators, ensuring that power transmission remains uninterrupted. These measures not only preserve the integrity of the electrical grid but also protect infrastructure investments, highlighting the invaluable role of suspension insulators as the unsung heroes of our power systems.

Materials and Innovations: Enhancing the Durability of Insulators

Modern advancements in materials science have led to the development of innovative substances that significantly enhance the durability of suspension insulators. Engineers are now utilizing high-performance polymers and ceramic composites which not only boost resistance to electrical stress but also increase resilience against environmental factors. Key benefits of these materials include:

- Improved weather resistance: Unyielding against UV deterioration and moisture-related damages.

- Enhanced mechanical strength: Capable of withstanding extreme wind and ice loads.

- Reduced weight: Facilitates easier installation and less strain on support structures.

Moreover, cutting-edge coating technologies have emerged, providing an additional layer of protection for insulators.These coatings can fend off contaminants that tend to build up over time, such as dust, dirt, and salt, which can compromise electrical performance. Below is a simple comparison table detailing various types of coatings and their features:

| Coating Type | Benefits |

|---|---|

| Hydrophobic coatings | Repel water and contaminants, enhancing self-cleaning properties. |

| Anti-UV treatments | Prevent degradation from sunlight exposure, prolonging lifespan. |

| Corrosion-resistant layers | Shield against corrosive elements, particularly in coastal regions. |

Maintenance Strategies for Longevity and Reliability in Power Systems

Effective maintenance strategies are crucial for ensuring the longevity and reliability of suspension insulators, the unsung heroes that support power lines. Regular inspections and monitoring of the insulators play a transformative role in detecting wear and tear before they escalate into notable issues. Key maintenance activities include:

- Visual Inspections: Conducting routine visual checks to identify any physical signs of damage,such as cracks or contamination.

- Electrical testing: Utilizing methods like power-frequency tests to gauge insulation integrity and detect potential faults.

- Cleaning Protocols: Establishing a schedule for cleaning insulators to remove pollutants and salt deposits, especially in coastal regions.

- Record Keeping: Maintaining detailed records of inspections, tests, and repairs to track the performance history over time.

Additionally, implementing advanced technologies can lead to enhanced maintenance strategies. Remote monitoring systems equipped with sensors can provide real-time data on the condition of suspension insulators, enabling proactive maintenance decision-making. A summary of essential maintenance technologies includes:

| Technology | Benefits |

|---|---|

| Thermal imaging | Identifies overheating components early. |

| Ultrasonic Testing | Detects corroded areas and defects. |

| Drones | Accesses hard-to-reach locations for inspections. |

Environmental Considerations: Balancing Functionality with Sustainability

As the demand for electricity increases, the necessity of integrating enduring practices in the production and use of suspension insulators becomes paramount. Manufacturers are increasingly focusing on materials that not only enhance performance but also minimize the environmental footprint.As an example, materials like silicone and polymer composites are emerging as popular alternatives to traditional ceramics, offering improved durability while being less energy-intensive in their production processes. Adopting such materials leads to a reduction in resource consumption and lower emissions during manufacturing.

Moreover, the lifecycle of suspension insulators is crucial for their overall sustainability. By emphasizing recyclability and longevity, manufacturers can reduce waste and promote a circular economy in the electrical sector. The table below summarizes key features of various materials used in suspension insulators, highlighting their environmental impacts:

| Material | Durability | Recyclability | Environmental Impact |

|---|---|---|---|

| Ceramic | High | Low | High energy use |

| Silicone | Medium to high | Medium | Reduced energy use |

| Polymer Composites | High | High | Lowest energy use |

Q&A

Q&A: suspension Insulators - The Silent Guardians of Power Lines

Q1: What are suspension insulators and what role do they play in power transmission?

A1: Suspension insulators are crucial components in the electrical transmission infrastructure. They are used to hold conductors or wires in place while ensuring that the electrical current flows efficiently. These insulators prevent the electricity from leaking to the ground, maintaining a secure line of communication and power flow between generation points and consumers. Think of them as the silent sentinels that keep the energy flowing without interruption.

Q2: How do suspension insulators work?

A2: Suspension insulators work by utilizing materials that are poor conductors of electricity, commonly ceramics, glass, or polymer compounds. These materials ensure that any electrical potential doesn't pass through them and instead directs the flow through the conductors. The design typically involves multiple units stacked together to increase the insulation's effectiveness and withstand environmental stresses, such as wind and temperature changes. This layered approach not only enhances their capability but also provides versatility and reliability in varied climates.

Q3: What are the different types of suspension insulators available?

A3: There are several types of suspension insulators, each tailored for specific requirements. The most common are ceramic insulators, known for their durability and weather resistance, and glass insulators, which offer high visibility and superior mechanical strength. Additionally, polymer insulators have become increasingly popular due to their lightweight nature and resilience against pollution and weathering.Each type has its unique advantages, making them suitable for various applications, from urban areas to remote landscapes.

Q4: Why are suspension insulators considered "silent guardians"?

A4: Suspension insulators earn their title as "silent guardians" becuase they operate quietly and efficiently, ensuring the safety and reliability of high-voltage power lines without drawing attention to themselves. Despite being largely invisible in the grand scheme of power infrastructure, they play a vital role in preventing outages and maintaining the structural integrity of transmission systems. Their enduring presence and functionality often go unnoticed until a failure occurs, underscoring their importance in the world of electricity distribution.

Q5: What factors influence the lifespan and maintenance of suspension insulators?

A5: the lifespan of suspension insulators is influenced by various factors, including environmental conditions (like sea salt and industrial pollution), mechanical stress (from wind and ice), and the material's inherent qualities. Regular maintenance is essential to identify and mitigate wear and tear caused by these conditions. Insulators may require periodic cleaning, inspections for cracks or deterioration, and, in some cases, replacement to ensure their effectiveness and longevity in the field.

Q6: Can you elaborate on the challenges faced by suspension insulators?

A6: Suspension insulators face multiple challenges, primarily from environmental factors.Pollution, humidity, and thermal cycling can lead to surface degradation, impacting insulation properties. Additionally, extreme weather events, such as storms or heavy snow, impose mechanical stress that can affect their structure. Engineers and manufacturers continuously work to innovate materials and designs that better withstand these challenges, ensuring that the silent guardians remain effective in their ever-crucial role.

Q7: What innovations are emerging in the field of suspension insulators?

A7: Recent innovations in suspension insulators focus on improving materials for enhanced performance and resilience. For instance, advancements in composite materials have led to the development of lighter, more durable insulators that can withstand harsher environments. Further, smart technologies are being integrated, allowing for real-time monitoring of insulator conditions. These innovations not only extend the lifespan of the insulators but also contribute to a smarter, more efficient energy grid.

Q8: Why is it critically important for the public to understand the role of suspension insulators?

A8: understanding the role of suspension insulators helps the public appreciate the complexities behind delivering reliable electricity. Awareness fosters support for infrastructure investments and developments,ensuring that the silent guardians receive the attention and resources they need for maintenance and upgrades. As consumers, recognizing the interconnectedness of power systems can also promote energy conservation and sustainable practices in our daily lives.

Conclusion: Suspension insulators silently safeguard our power lines, maintaining a critical link between energy production and consumption. Their importance in the vast network of electrical transmission cannot be overstated, and their evolving technology promises to enhance performance in the face of changing environmental challenges.

Concluding Remarks

As we draw the curtain on our exploration of suspension insulators, the unsung heroes of our power transmission networks, it's clear that these seemingly simple components play a crucial role in our daily lives.From their ability to withstand the harshest of weather conditions to their silent vigilance high above us,suspension insulators are the steadfast guardians of our electrical infrastructure. They ensure that the flow of energy remains uninterrupted, safeguarding both the reliability of our power supply and the safety of those living and working beneath the vast web of power lines.

In a world were technology continues to evolve at an unprecedented pace, the importance of these silent protectors cannot be overstated. As we look to a future filled with renewable energy and innovative power solutions, understanding and appreciating the function of suspension insulators becomes vital. Just as they support the very lines that connect us to energy, let us embrace our awareness of their role in fostering a more sustainable and connected world. In doing so, we honor not just the technology but the diligent engineering that keeps our lights on and our lives moving forward.